Niseko, Toya-Usu and Shiraoi are three Hokkaido destinations for travellers who want to feel close to the communities they’re visiting.

The new generation of high-performance wood materials offers unexpected hi-tech possibilities to the worlds of design and architecture.

Designed to be biodegradable and carbon neutral, the materials of the future are destined to be bio-manufactured, bio-derived, biobased. In all likelihood, to keep their impact low, we will arrive at an idea of ad-hoc cultivated materials. This scenario, which is changing the parameters of innovation, asks us all to rethink the way we mentally categorise materials. And it requires designers and architects to change the way they choose and use materials. All materials, including the most traditional, are being updated in technical terms. Foremost among these is wood, which, in view of a sustainability profile increasingly aimed at impact minimisation and sustainable forest management, is surprisingly acquiring performance features that are entirely comparable to those of hi-tech materials.

Driven by hi-tech innovation, made possible by changes performed at the level of its nanoscopic structure and transformation processes, today wood offers an extraordinary plurality of languages, both technical and formal, while always remaining a natural material. Wood can be transparent, liquid, as resistant as steel or concrete, expanded, 3D-printable, flexible, sewable. And much, much more.

This is a fascinating world, and, for this exact reason, it requires not only moderation in decisions, but also and most of all new formal languages to establish itself. This is what happened in the 1980s, when, thanks to the new technology of ultra-thin wood veneers – which, for the first time, allowed any essence to be recreated in natural form through thin veneers of real wood – Ettore Sottsass paved the way for contemporary wood. With great foresight, and as the iconoclast that he was, Sottsass created Alpi (pictured above), showing that wood could remain true to its substance while becoming avant-garde in its forms. Only thus will bio-tech wood truly be able to achieve plurality, becoming an icon of sustainable beauty and transcending its status as a powerful and timeless natural icon, faithful to itself across the centuries.

In 2011, anticipating scientific reality, Japanese design studio Nendo – aiming to create the illusion of transparent wood – produced an acrylic table designed to have the shape, parts assembly, and surface grain of wooden boards. This visionary design foreshadowed an imminent future, where what is natural takes on unexpected forms. This future is here.

In the last few years, multiple university materials research centres at the international level have worked hard to create wood that allows light to pass through. The advantages that a natural, potentially low-cost material such as wood could have for the world of design if it were equipped with a new, functional transparency are self-evident. It would allow for a world of sustainable and cheap windows, radically changing technological objects that currently use glass as an interface, from solar panels to electronic devices. But the real revolution lies in the fact that, by itself, the transparency of wood leads us to imagine a new aesthetic of sustainability, where we can imagine extraordinarily beautiful, high-performing technology that is emotionally close to feeling natural.

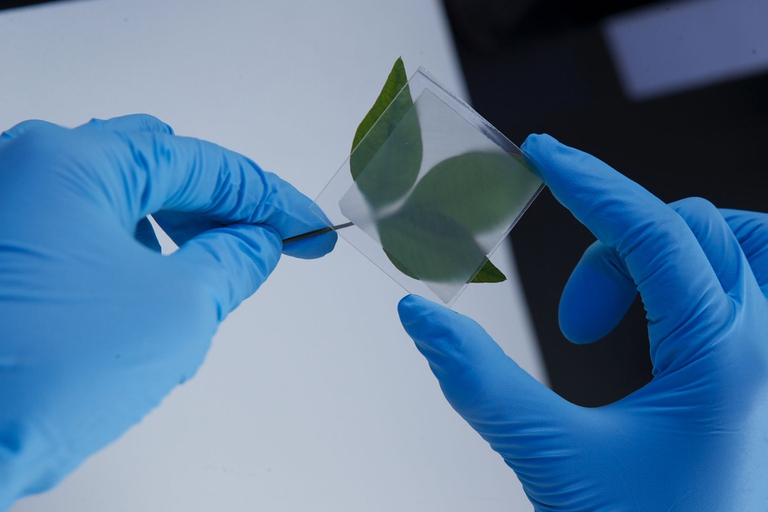

Technically, the process through which a certain degree of transparency in wood can be obtained has been possible for several years, thanks to the use of nanotechnology. Lignin, a biopolymer component of cell walls (responsible for the solidity, opacity, and colour of wood, ed.), is removed from the material without damaging its microstructures. The pores it leaves behind are filled with a transparent polymer to restore the mechanical properties of the original material, but with new optical qualities. The wood that has been obtained from this process is characterised by soft transparency, like that of frosted glass, which lets light through very well and modulates images with delicate blurs.

Only lately, however, have encouraging results been achieved in applying these processes to large-scale production. This happened thanks to startups created specifically by experts in cellulose technology, which entered the field with the goal of bridging the gap between academia and industry. The first extraordinary results of these important collaborations have been achieved in Europe.

Process methodologies in this field are constantly being updated, with some still being assessed in terms of their overall impact. However, published research offers hope that in a few years these new materials will be ready to be deployed in the projects of designers and architects.

KTH, in Stockholm (the Swedish Royal Institute of Technology), was the first to reveal the excellent results obtained by Professor Lars Berglund of the WWSC (Wallenberg Wood Science Center, a KTH partner), who made wood transparent for the first time through the chemical removal of lignin in solution. The pores left by the lignin, filled with a polymer whose refraction index corresponds with that of wood, allow light to propagate through the material, which thus becomes translucent. The WWSC’s research is primarily aimed at putting on the market a structural wooden alternative to glass, suited to the creation of solar cells that would thus use a low-cost, renewable resource, with the added environmental benefit of the low density and low thermal conductivity of the new material.

It’s clear that this “wood as glass” could transform the architecture of tomorrow, in the case where it is used even in buildings’ facades. However, the advantages would not stop at light filtration. In addition to transparency, this new wood created by Swedish researchers could have other significant benefits, such as the ability to release or accumulate heat much better than glass. “Working on the type of filler for the pores left after the lignin is removed can lead to very interesting self-regulating thermal properties being achieved,” explains Céline Montanari, a member of Lars Berglund’s team, in an article published in 2016, in the early days of their research.

Montanari is referring to the filler being used, which is based on phase change materials (PCMs): “these are also known as latent accumulation materials because they are able to change from a solid to a liquid state, and vice versa. In other words, these fillers, passing from a liquid to a solid phase, release the heat they have stored, or, conversely, they can absorb heat. This means they are able to store large amounts of heat”. PCMs can organic or inorganic, and the Swedish team initially used a biodegradable, non-toxic PCM called polyethylene glycol (PEG, a polymer used in cosmetics and medicine, which was discussed recently with regards to the production of certain Covid-19 vaccines, ed.).

Recently, however, the Swedish researchers announced new interesting results in the quest for full sustainability: “Five years after having introduced transparent wood, we have found a way to make the composite 100 per cent renewable – and more translucent – using a citrus-based transparent bioplastic as filler material,” as described in an interesting article published on 2nd May 2021 in Advanced Science. The fundamental feature of the results achieved in Sweden is that it is possible to have a load-bearing material with very competitive structural, as well as optical properties, while other transparent woods remain mostly decorative materials.

Another group working in the field of making wood transparent is the CMI (Center for Material Innovation) at the University of Maryland, in the US, whose researchers, led by Professor Hu Lianbing, have obtained translucent wood using an epoxy bio-resin. The CMI has mainly invested in the possibility of finding an alternative process to chemical de-lignification in solution, which generally uses large amounts of chemicals and energy. In 2019, the US-based team devised a “chemical brushing” lignin removal technique, which can activate transparency over short time frames by exposing the material to the sun. The resulting transparent wood is thin (approximately 1mm thick), has an optical transmittance (a material’s ability to let light pass through, ed.) of 90 per cent, and, since the brushing process requires the chemicals to be applied similarly to paint, it could be possible to design ad-hoc transparent patterns, adding decorative effects to the material.

Wood biocomposites with high optical performance have a lot to offer, especially to future technologies. Concepts range from using wood for heat storage to having wood panels with integrated lighting functions, with exciting applications for smart windows and use as an interface medium in electronic devices.

The hunt for bio-hi-tech materials is at the heart of the French project Woodoo, funded by the European Union in 2017 following a proposal from French entrepreneur, architect, and biologist Timothée Boitouzet. His company, which is also called Woodoo, works on cellulose nanotechnology to develop new wood-based materials with technological applications. Boitouzet explained to CORDIS (the EU Community Research and Development Information Service) that “Woodoo selectively extracts lignin and replaces it with speciality polymers. The new materials feature unprecedented mechanical strength, durability, fire resistance and optical properties. Woodoo uses local wood materials including low-grade wood species (beech, birch, pine and aspen), all sourced from sustainably managed EU forests within 300 km of the manufacturing plant. By replacing emissive primary building elements, Woodoo’s biomaterials will be 17 times less energy-intensive than glass, 130 times less than steel and 475 times less than aluminium. Rather than a primitive material that is the antithesis of innovation and futuristic design, wood is transformed through technology into a new generation of bio-based, hi-tech, and relatively inexpensive materials that could deeply change our relationship with technology. With Woodoo, we aim to work at this frontier, collaborating with world-class automobile design manufacturers”. Woodoo is also the name of one of the Paris-based company’s products: a hi-tech, translucent, and touch-sensitive wood with the transparency of amber, recently developed to produce digital interfaces.

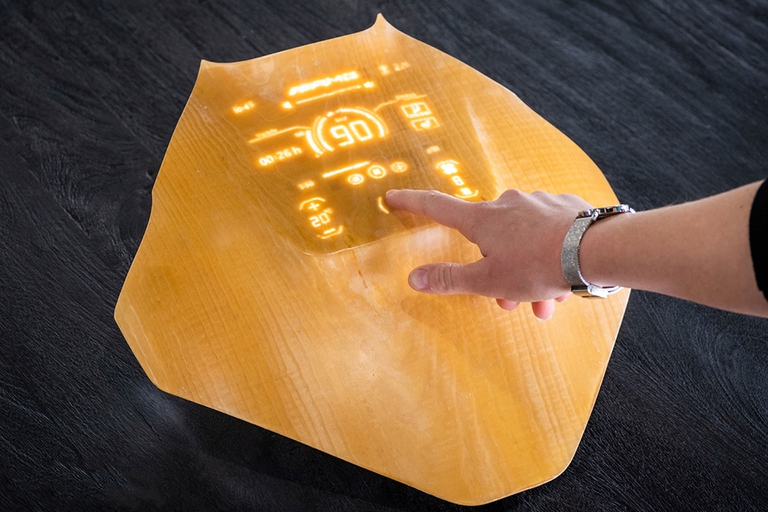

Just like the transparent table by Japanese design studio Nendo, launched at the Milan International Furniture Fair in 2011, another project from Japan, called mui, made its first appearance in Milan to make itself known to the international design community. This happened during the city’s design week, following the conclusion of a Kickstarter campaign in April 2019. Today, mui Lab is a Kyoto-based startup specialising in “calm interfaces”. Its flagship product, the mui display system, consists of an interactive transparent wood panel that can control IoT devices and connect to the Internet.

When switched off, mui looks like a simple hardwood panel, but with a touch of your fingers on the natural surface a display lights up inside the device that allows you to regulate the light and temperature in your smart home, check the news and weather, play music, send and receive text and voice messages. This project draws inspiration from the Taoist philosophy of mui shinzen, whose literal meaning is akin to “doing nothing”. However, for mui Lab – as co-founder and CEO Kaz Oki explains – “it means proposing ‘calm technology’ that can bring a sense of nature into today’s digital living by harnessing the company’s engineering power and leading-edge technologies”. mui has obtained intellectual property rights on its interactive wooden panel.

In 2012, Italian fashion brand Gucci, implementing Safilo Group and Kering Eyewear’s new sustainable luxury policies, experimented with liquid wood. This material had never previously been used in this sector, and it was deployed for the production of certain sunglasses models, with the aim of replacing traditional plastic materials.

Naturally, the line between being fully sustainable and simply reducing the quantity of plastic material used is determined by the possibility of ensuring, even in the case of liquid food, a 100-per-cent bio-based mix in experimental formulations, where, for example, natural wood fibre is united with materials like hemp or linen using natural additives, like waxes. Liquid wood bioplastics are materials made from 100 per cent renewable raw materials, where lignin discarded from paper production (or other wood processing residues) is used in combination with other materials to obtain printable “pellets” as with any other plastic material. Therefore, these are low-impact materials.

One of these low-impact “liquid wood materials”, developed by the engineers at Germany’s Fraunhofer Institute, has become a mass-marketed material sold by biopolymer company Tecnaro through the Arboform brand. The material is biodegradable, combustible, and resistant to solar action, and it can be altered to make it flame-resistant. Given the high timber production of some European countries, especially in Scandinavia, countries such as Sweden have made significant investments into this type of composite, based on wood processing residues and biopolymers. Durasense, by Stora Enso, is another example of these new materials, created using wood fibres and shavings alongside bio-based polymers.

The impressive results being obtained in the production of bioplastics, on the one hand, and the repurposing of natural residues to reduce the impact on forests, on the other, foster the reasonable belief that printed liquid wood objects could soon represent an excellent opportunity for environmentally respectful design to generate innovation. Liquid wood made from 100 per cent renewable raw materials can be injection moulded, extruded into sheets, and – while this is still in the experimental phase – it’s starting to find applications in interior design (furniture or parts of cars’ interiors).

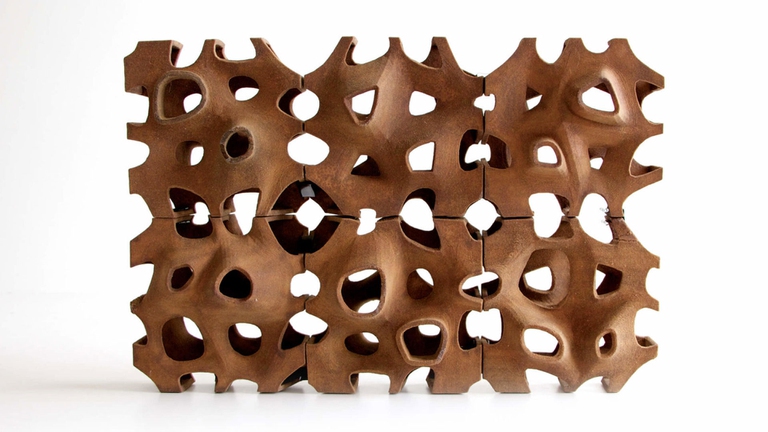

Having taken up the challenge of technology, wood further pushes its centre of mass from nature toward industrial design. Today, it’s possible to make a bio-based 3D-printable material from wood. Mixtures of printable wood composites and plastic materials have already been available for a few years for design applications, but there are still relatively few bio-based 3D wood materials.

In a recent article, researcher and architect Blaine Brownell, an expert in advanced sustainable materials for architecture and design and director of the School of Architecture at the University of North Carolina, warns that 3D-printed wood presents a paradox. Despite providing an avenue for the reuse of wood processing waste, it could have negative environmental outcomes if the other components in the mix, necessary in the additive manufacturing process (another name for 3D printing, where the material is added layer after layer until the final volume is achieved, ed.), are not chosen with care.

In his article, Brownell explains that normally, wood-plastic composites (WPCs) are materials comprising only 30 or 35 per cent recycled wood fibres, while the remaining 70 or 65 per cent is made up of copolyesters or, in the best-case scenario, by polylactic acid (PLA, a bio-based polyester derived from plants like corn, wheat, or beets, ed.). Conversely, “researchers at the WWSC created a printable medium from cellulose nanofibrils mixed with hydrogel. This gelatinous slurry, composed of over 95 per cent water, is suitable for printing three-dimensional structures that retain their shape when dried in controlled conditions”.

This pioneering sector of design is still not widely worked on. Among its few exponents we find Forust Corporation, a California-based company that uses wood powder with bonding agents derived from recycled agricultural waste. In collaboration with creative think-tank Emerging Objects, Forust has created a series of experimental 3D wood structures, with original organic forms. The colours of these objects, however, are based on tones in the brown and straw range, while textures and veinings remain as close to natural as possible.

Another pioneering innovation in this field, which is already seeing real-world applications, is structural wood that can be used to build skyscrapers. Mjøstårnet, the tallest wooden skyscraper built so far, was created in Brumunddal, near Norway‘s capital, Oslo, based on a project by the Voll Arkitekter studio. The 85.4-metre-tall structure was built using cross-laminated timber (CLT, where solid-sawn panels are layered in an interlaced pattern for extra strength), with columns made from glued laminated timber (glulam), floor elements made from laminated veneer lumber and rounded pergola beams to reduce wind loads. To help it withstand structural demands, the building is anchored to the bedrock up to 56 metres below ground, and despite using 300-millimetre concrete slabs on its higher floors to ensure stability, it produces 65 per cent less CO2 than concrete and steel.

This is just the first in what will be a new generation of large-scale wooden architecture, which will be a key part of eco-friendly cities. Researchers at the Sumitomo Research Laboratory in Tsukuba, Japan, envision “cities transformed into forests through wooden skyscrapers, themselves rich in green spaces”. This idea is at the core of W350, a technological project to build a 350-metre-tall wooden skyscraper by 2041 when Sumitomo Forestry will celebrate the 350th anniversary of its founding.

Designed by Tokyo-based architecture studio Nikken Sekkei, in collaboration with Sumitomo’s Tsukuba Research Laboratory, the W350 skyscraper will be a wood-steel hybrid. It takes on the ambitious task to prove wood’s reliability in hi-tech applications and promote the recovery of Japan’s wood industry, which today is focused heavily on the reforestation of rural areas. An ideal thread ties the project to the history of Japan, whose tradition created temples like the Ise Grand Shrine, much loved by Carlo Scarpa.

In a design experiment in the 1980s, Italian designer Marco Ferreri conceived Less Chair, an innovative chair where a thin wood veneer was coupled with an expanded foam to obtain a “soft” wooden seat. Fifteen years later, in 1996, the Laleggera chair range, designed by Riccardo Blumer, was produced thanks to new technology from the automotive industry, which Renato Stauffacher purchased for Italian design company Alias, which he directed. The innovation came about after three years of experimentation, applying hot polyurethane foam printing to a super-light hardwood structure within five-millimetre-thick sheets, pre-cut according to the seat’s form. The wood thus performed another (apparent) structural magic spell, where solidity and extreme lightness could coexist (the chair weighs 2kg).

Thirty years on from those design innovations, wood can now really be as light as foam. The first ultra-light wood was developed a few years ago in Asia, by a team of researchers at the National University of Singapore. The team created a cellulose aerogel derived from the processing of paper: cellulose paste, mixed with a gas, generates a solid foam whose performance is fully comparable to plastic-based expanded foams.

A few years earlier, in Sweden, a startup called Cellutech (launched to act as an accelerator for the development of innovative wood-based materials, in close collaboration with industrial partners and researchers at Stockholm’s WWSC) created a renewable, bio-based expanded material and became a part of the Stora Enso Innovation Center for Biomaterials. Finally, in 2020, the first production plant for highly impact-resistant cellulose foam opened in Sweden. This new material, made from renewable wood, is biodegradable and, last but not least, it can be recycled alongside normal paper and cardboard. This makes cellulose foam particularly interesting in terms of the design of products that we use every day.

We are used to referring to wood in the singular, but now more than ever wood is a material that exists in a plurality of forms. After decades of innovation directed at artificial materials, with designers always questing for super-performance, making no distinction between materials with higher or lower impacts, wood has now made it to the forefront. With its many hi-tech features, wood can lead an extraordinary comeback for natural materials, where choices based on responsible forestry are just the starting point. Transparency, resistance, lightness, moldability at different scales, but most of all the growing capacity to alter its properties without losing the original matrix, all ensure that the new woods (and their derivatives) can be the protagonists of a new, powerful naturalness, paving the way for responsible design. In this context, these innovative materials can contribute, by experimenting with new qualities and aesthetic properties, to the establishment of a new, cutting-edge bio-circular economy, without forgetting tradition.

Siamo anche su WhatsApp. Segui il canale ufficiale LifeGate per restare aggiornata, aggiornato sulle ultime notizie e sulle nostre attività.

![]()

Quest'opera è distribuita con Licenza Creative Commons Attribuzione - Non commerciale - Non opere derivate 4.0 Internazionale.

Niseko, Toya-Usu and Shiraoi are three Hokkaido destinations for travellers who want to feel close to the communities they’re visiting.

We talked to World Happiness Summit organiser Karen Guggenheim about the connection between the planet’s health and our happiness.

A group of experts in Tokyo suggested pouring radioactive water from Fukushima into the open sea. A marine biochemist explains the consequences of this absurd decision.

By recovering clothes discarded in the West, Togolese designer Amah Ayiv gives them new life through his high fashion creations.

All catwalks in July will be broadcast online: after Paris, it’s Milan Digital Fashion Week’s turn. And the biggest beneficiary is the environment.

Disabled travellers need not fear Japan. Accessible Japan founder Josh Grisdale tells us about his commitment to opening the country’s doors to everyone.

Kalongo Hospital in Uganda is on high alert. Medics are facing the pandemic amid an already precarious healthcare situation, in a country with only 55 intensive care beds.

Indigenous peoples in the isolated region are suffering from poor access to health, with several cities becoming hotspots of coronavirus in the Amazon. Indigenous leaders, health experts and NGOs are calling for international help.

The book Fashion Industry 2030 aims to contribute to reshaping the future through sustainability and responsible innovation. An exclusive opportunity to read its introduction.